The role of 3d printing in modern manufacturing

The world of manufacturing is ever-evolving, with new technologies continually reshaping the way we produce goods. Among these innovative technologies, 3D printing or additive manufacturing has made a significant impact. This game-changing technology has opened up new possibilities in manufacturing, from medical devices to automotive parts, transforming traditional production methods to create a more efficient, cost-effective, and sustainable process.

The Rise of 3D Printing

3D printing, also considered an additive process, is a technology that creates three-dimensional objects from digital models by layering materials. Unlike traditional manufacturing methods, which often involve cutting away excess material, 3D printing builds products layer by layer, thus significantly reducing waste.

A lire également : Building an inclusive recruitment strategy in the modern workplace

As a technology, 3D printing was developed over 30 years ago, but it’s in the last decade or so that it has truly revolutionized the manufacturing industry. This rise can be attributed to advancements in materials, printing technology, and software, which have all broadened the scope of what can be achieved with 3D printing. Today, we find its applications in a wide range of industries, from aerospace to fashion, proving its versatility and potential.

Applications in Various Industries

One of the most striking benefits of 3D printing is its wide array of applications. Its ability to create complex shapes and structures with precision has made it a vital tool in various industries.

En parallèle : Cultivating a positive workplace culture: essential tips

In the medical field, 3D printing has created a revolution. From producing personalized prosthetics to bio-printing tissues and organs, 3D printing has proven to be a game-changer. The FDA has already approved several 3D printed medical devices, including dental implants and surgical instruments, signifying its growing acceptance and relevance in this sector.

The automotive industry is another sector that has greatly benefited from 3D printing. It has made it possible to produce lightweight, complex parts that were previously impossible or costly to manufacture traditionally. This has improved efficiency, reduced production time, and opened up possibilities for custom-built cars.

The aerospace industry, known for its strict standards and precision requirements, has also embraced 3D printing. The technology’s ability to create lightweight, durable parts has made it an invaluable asset in the production of aircraft and spacecraft components.

Materials and Processes in 3D Printing

3D printing uses a variety of materials, including plastics, metals, ceramics, and even biocompatible materials. The choice of material depends on the desired properties of the printed object, such as strength, flexibility, and resistance to temperature or chemicals.

The process of 3D printing involves several steps. First, a digital model of the object is created using computer-aided design (CAD) software. This model is then sliced into thin layers by slicing software, which generates a code that instructs the 3D printer on how to form each layer. The printer then deposits or fuses material layer by layer, following the instructions in the code, until the object is completed.

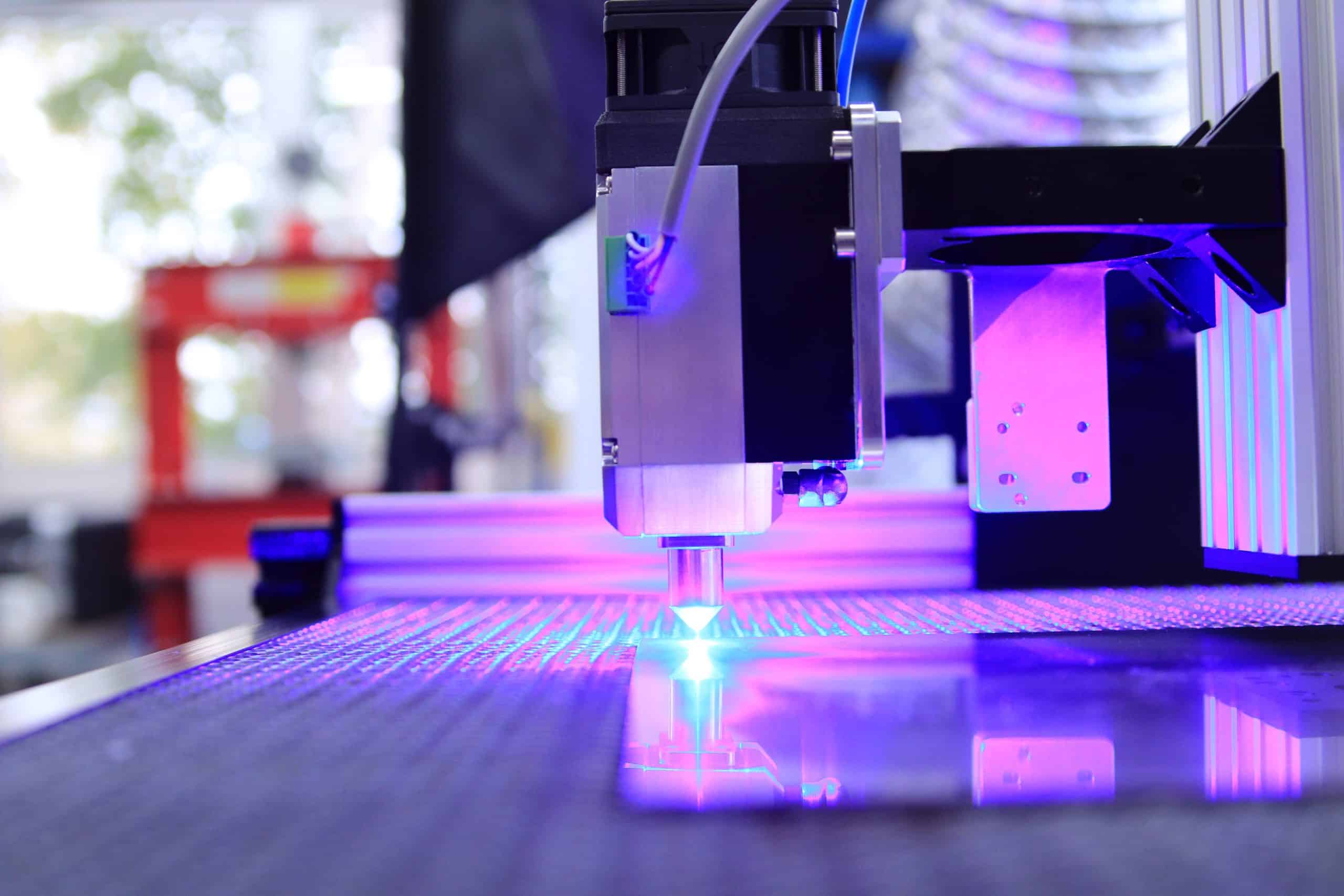

The two most common methods of 3D printing are Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). FDM uses a heated nozzle to extrude plastic filament, while SLS uses a laser to fuse powdered material. Both methods have their advantages and are suitable for different applications.

The Future of 3D Printing

Given the speed at which 3D printing technology is advancing, it is safe to predict that its impact on the manufacturing industry will only increase. As new materials are developed and printing technology becomes more sophisticated, we can expect to see more complex and innovative products being created.

In the future, 3D printing could enable more sustainable manufacturing processes by reducing waste and energy consumption. Moreover, it could democratize manufacturing by making it possible for individuals or small businesses to produce their own products, thus challenging the traditional mass production model.

As we progress into the digital age, the role of 3D printing in modern manufacturing will continue to evolve. It is a promising technology that holds the potential to transform the way we create and consume products, making it a fascinating field to watch in the years to come.

References

To gain more insights on the topic, scholars can refer to various research papers, articles, and reports available online. Websites such as Crossref and PMC offer a vast collection of scholarly writings, providing DOI for each document for easy accessibility. The continuous research in the field of 3D printing further testifies to its importance in modern manufacturing.

Advancements and Challenges in 3D Printing

In the world of technology, progression is a constant factor. Over time, 3D printing has flourished with remarkable improvements in speed, accuracy, and cost-effectiveness. The advancements in additive manufacturing are largely attributed to relentless research and development efforts. The refinement of 3D printing technology has made it possible to produce larger parts, print with multiple materials in a single print, and achieve unprecedented precision.

However, like any other technology, 3D printing also faces several challenges. A key concern is the intellectual property issues that arise with the ease of duplicating products. The quality and consistency of printed products can be highly variable, depending on the equipment used, the material, and the operator’s skill level. Also, while 3D printing can reduce waste compared to traditional manufacturing methods, the energy consumption can be higher. Finally, the availability and cost of printing materials may also pose a challenge to the widespread adoption of this technology, particularly in developing regions.

Despite these concerns, the future of 3D printing appears promising. To tackle these issues, continuous research is required, and this can be facilitated through resources such as Google Scholar, PubMed, and CrossRef. These platforms provide free access to a plethora of invaluable research material.

Conclusion: The Transformative Potential of 3D Printing in Manufacturing

3D printing technology has undeniably reshaped the landscape of manufacturing, offering a paradigm shift from traditional manufacturing techniques. Its ability to create intricate designs, reduce waste, and personalise products are some of the key advantages that have positioned it as a cornerstone in the modern manufacturing process.

While the technology poses some challenges, the potential benefits far outweigh these. Its role extends beyond just production, influencing the entire supply chain, from design to distribution. As technology continues to advance, these challenges will likely be addressed, paving the way for a more sustainable and efficient manufacturing process.

In conclusion, the future of 3D printing in modern manufacturing is bright. The technology is evolving rapidly, and with continuous research and development, it will continue to revolutionise various industries. For those interested in exploring more about the transformative potential of 3D printing, there are numerous free articles available on PMC, CrossRef, and PubMed. With a simple click, one can open a separate window to delve into a wealth of knowledge, substantiating the significance of 3D printing in modern manufacturing.